Festival of Trees 2023

Year: 2023

Scope: Group brainstorming; development of a real-time visualizer; development of clash detection tool; feedback pin-ups and group crits; material testing and prototyping; development of laser cutting files, development of assembly handbook;

Collaborators: Co-workers at DIALOG

In 2023, I joined DIALOG’s Festival of Trees team, volunteering to help design, construct, and deliver a one-of-a-kind holiday tree to the University Hospital Foundation’s annual cornerstone fundraising event.

I convinced the group to use technologies we’d never employed on a Festival of Trees project before, including parametric modelling to visualise different possibilities before finalising the design, and laser-cutting to quickly and precisely fabricate the parts we needed.

While our new tools gave us a boost, it still took significant hands-on effort to physically put the pieces together, including a custom wood-worked frame, and integrated lighting.

The tree was a hit at the festival, selling on the first night and winning second place in the show. The project’s success even helped convince our studio’s technology and leadership teams to purchase a laser cutter for our maker space.

a teammate's Sketches from our initial meetingA teammate's sketch of our design conceptTheme & Concept

The theme of the 2023 festival was “snow globes”. We began with a wide-open brainstorming session where we sketched ideas, discussed possible materials, fabrication methods, and concepts that could inform the design and drive our process.

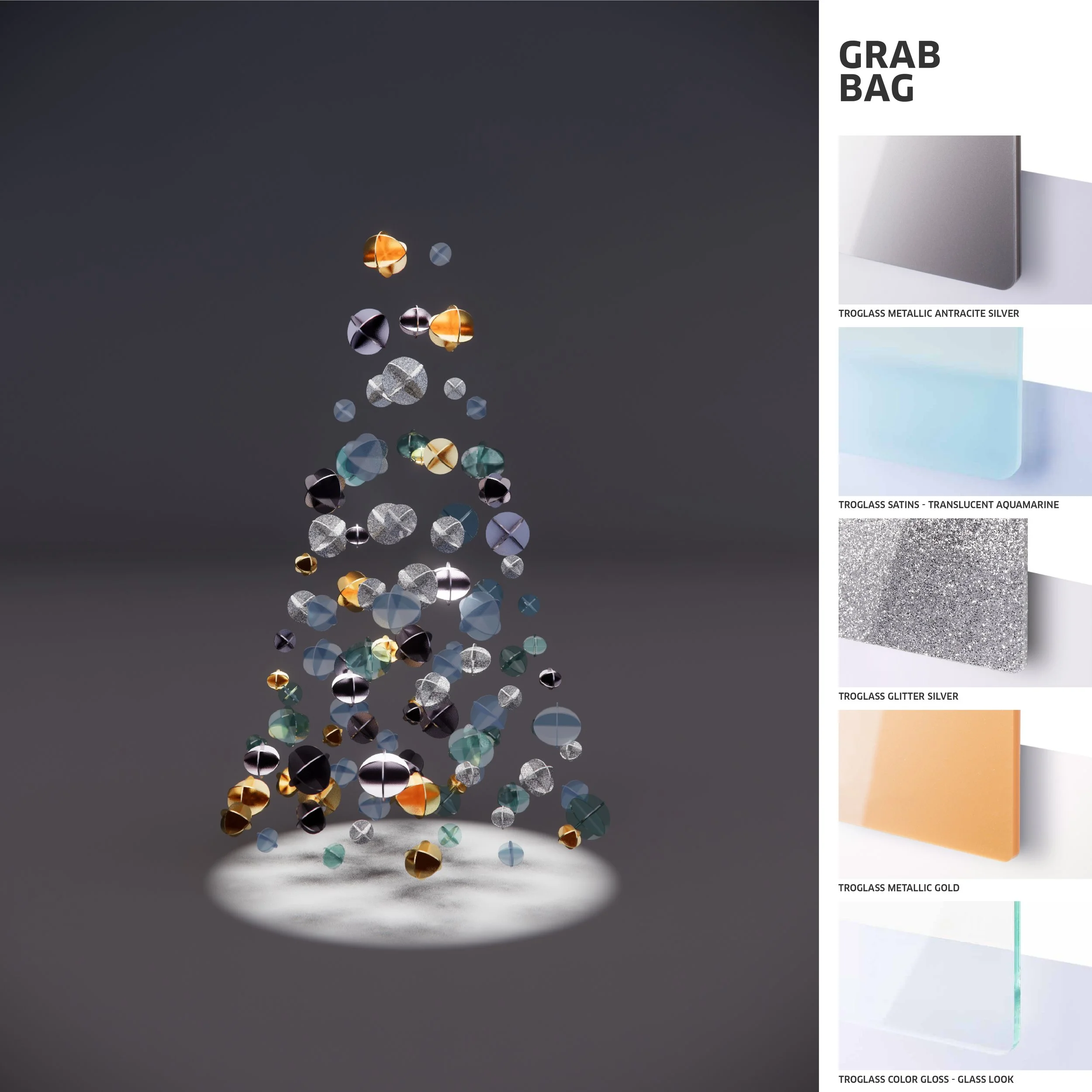

We came to a consensus on a design concept: we would create a collection of laser-cut “globe” shapes out of different colours and transparencies of acrylic. We would suspend them on fishing line to make them look as if they were floating, and arrange the globes so they formed a conical tree shape.

early parametric studies, testing different base diameters, globe sizes and densitiesshifting the design parameters in our model-linked script could create vastly different resultParametric Generation + Visualisation

As soon as we landed on a design concept, we began to ask ourselves more and more specific questions about the design. How tall should the tree be? How wide at its base? How many globes should we use? On how many separate lines should they be arranged? Should they all be the same size, or should the sizes vary? If we used different sizes, should they be intermixed or arranged by size? What colour should the globes be? Should they be the same colour or a combination of different colours? What should the ratios of the different colours be? What kind of structure should hold up globes?

We could imagine taking the design in many different directions, answering the questions above in so many different combinations that the possibilities began to feel overwhelming.

To help with this, I volunteered to create a custom parametric model and script that would allow us to control the answers to those questions as independent variables and preview the resulting design.

I brought a live interactive version of the model to one of our team meetings, and we spent most of our time testing out the wide range of potential designs it could produce. As we played with the variables, we began to gravitate toward certain looks, and we locked in some key decisions about the tree’s dimensions, the globe size variations we wanted to include, and the overall number of globes to be included.

A pin-up of different structure optionsmaterial optionslaser-cut globe prototypesPin-ups, prototypes, discussions, and decisions

We also found ways to make design decisions outside of meetings, particularly by printing out design options and pinning them up in high-traffic areas of the studio where anyone, not just our core team of volunteers, could see the most up-to-date iterations of the design and weigh in on what options they liked best.

I pinned up several different colour and finish combinations, which helped us resolve our material choices. I pinned up large-scale images of different structural solutions to support the globe-strung lines, and seeing them side-by-side quickly made the right decision clear. I even pinned up a prototype laser-cut globe with our print-outs for people to see and touch. I also kept a couple of globes on the side of my desk, which prompted even more discussions about the project among the wider studio team.

A sample laser cutting fileAutomated cutting layouts

Confident in our direction, our team moved into production mode. We had one team member volunteer to construct the wooden base and post that would give the tree its structure. Another team member would source lights and electrical supplies to light the tree. My task was to laser-cut the flat acrylic stock that would become the globes.

I leveraged the data-rich model we had already created to automate many of the otherwise tedious steps in preparing files for laser cutting. I was able to input the model geometry into a custom script that read the size and material data for each globe, took into account the size and thickness of the acrylic material we were using (which varied subtly from sheet to sheet), and generated nested cutting plans ready to go straight to the laser.

samples from the Assembly handbookThe Assembly Handbook

Since our team was working during lunch break and evenings, I anticipated that assembling the tree would likely unfold over multiple sessions and involve different people rotating in and out to help as they were free, including myself.

To help the process go smoothly, I put together a printed assembly handbook, similar in spirit to an IKEA manual, with simple diagrams and instructions. In its finalised form, our tree featured eighteen separate fishing lines, each strung with five globes. To match our design model, we needed to put the correct sizes and colours of globes at precise locations along each line. I wanted the handbook to show this information in simple, easily legible diagrams. Once again, our data-rich parametric model and some quick scripting made things easy. I input the model geometry and, with a few clicks, generated a unique, annotated diagram for each line.

Teamwork, making the dream work

The structural, electrical, and laser-cut elements all came together as planned. The assembly process went smoothly and we had a lot of fun!

The tree on display at the Festivala rendered view of our finalized designRendering vs. Results

Our team took great pride in what we had created together, particularly because the finished tree so closely matched the digital version we had created together. Too often in our industry, idealized renderings don’t match reality. This was a delightful exception.

More importantly, we were pleased to learn that the tree sold for its asking price and that our efforts had successfully benefited the University Hospital Foundation.